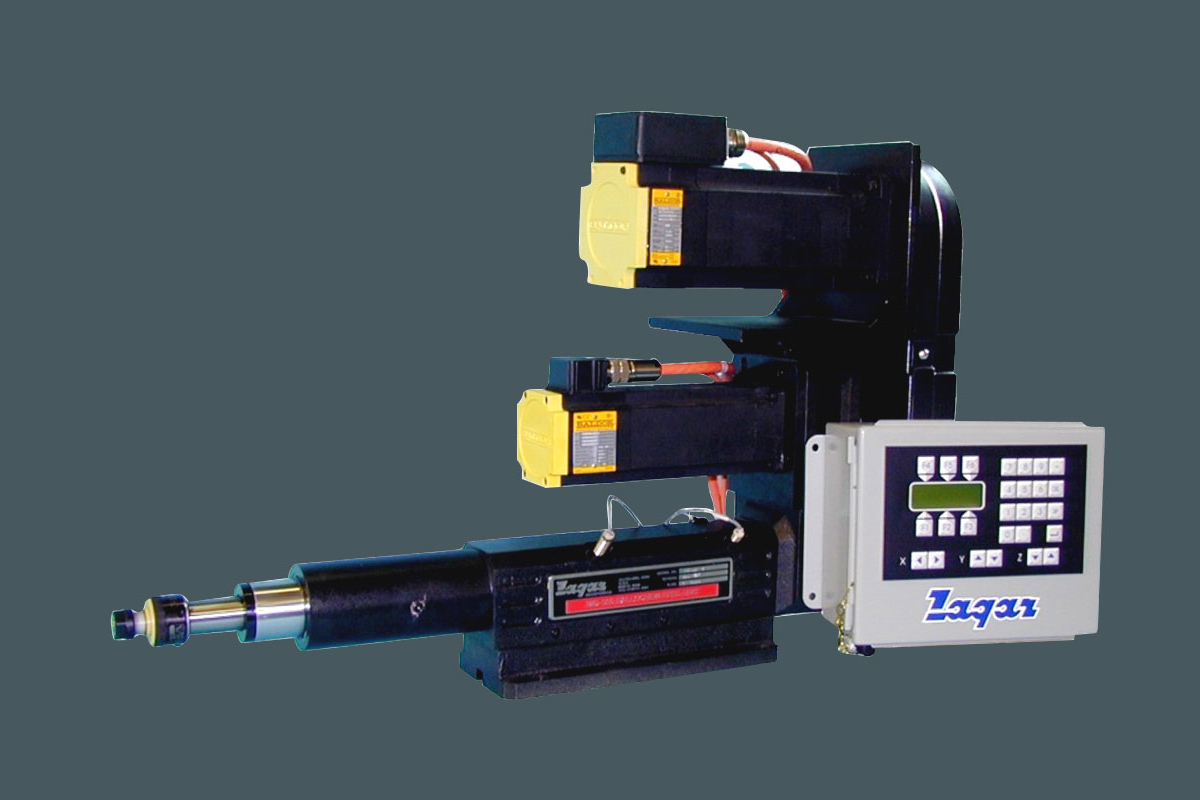

MECHANICAL QUILL (MQ) FEED UNITS

Engineered for all holemaking needs, any pattern, any material

Known for the crank-style multiple spindle drill head, Zagar can place more drills, taps, reamers, and other rotating tools closer than any other manufacturer. Heads are also available with gear and flex drive spindles.

Apply the latest machine tool technology to your production needs with Zagar ball screw feed units

Zagar ballscrew feed units are actuated through a servomotor. Available spindle drives range from a simple, fixed speed motor to a high precision, brushless servo or vector motor. We also provide complete one or two-axis fully programmable servo control packages. The flexibility of the units leads to virtually unlimited applications.

Features & Benefits:

- Ballscrew on centerline of spindle axis resulting in maximum thrust efficiency with no offset loading

- Independent ballscrew and quill assembly reduces repair costs

- Full stroke can be programmed for any combination of rapid and feed

- Rugged spindle bearings deliver high qualify hole finish and load capability

- Through-the-spindle coolant options standard for applications such as high pressure gun-drilling

- Synchronous HTD style belts for high horsepower capability, longer life and low-noise operation

- Fully enclosed pulley and belt guard for operator protection

- Detachable mounting base (MQ-150 only)

- All models capable of drilling or tapping type application

- Ready-to-run servo control options in single and dual axis versions include motors, amplifiers, and programmable control, all in a NEMA 12, fused enclosure

Spindle Motor Options:

- Standard servo control packages are available for all units as fixed speed single axis, variable speed single axis, or dual axis servo

- All control packages are fully programmable and have additional user I/O available

- All servo motor sizes are brushless, AC servo type

- Spindle motor options include .5 to 10 HP standard AC fixed speed, variable speed AC inverter controlled, 2 to 10 HP vector and low-inertia AC servo motors

- The programmable controller (1 or 2 axis), amplifiers, power supplies and electrical components including fusing and contactors for E-stop and main power are housed in a NEMA 12 enclosure

- Quick connect cables are wired and ready for connection to motors (servo only)

- Programming services are available to customize any application

- Zagar specifies quality controllers including Allen Bradley, Rexroth, Baldor, and Seimens for optimal productivity and capability, but can work with virtually any system to meet customer needs