PNEUMATIC AND HYDRAULIC THRUSTERS

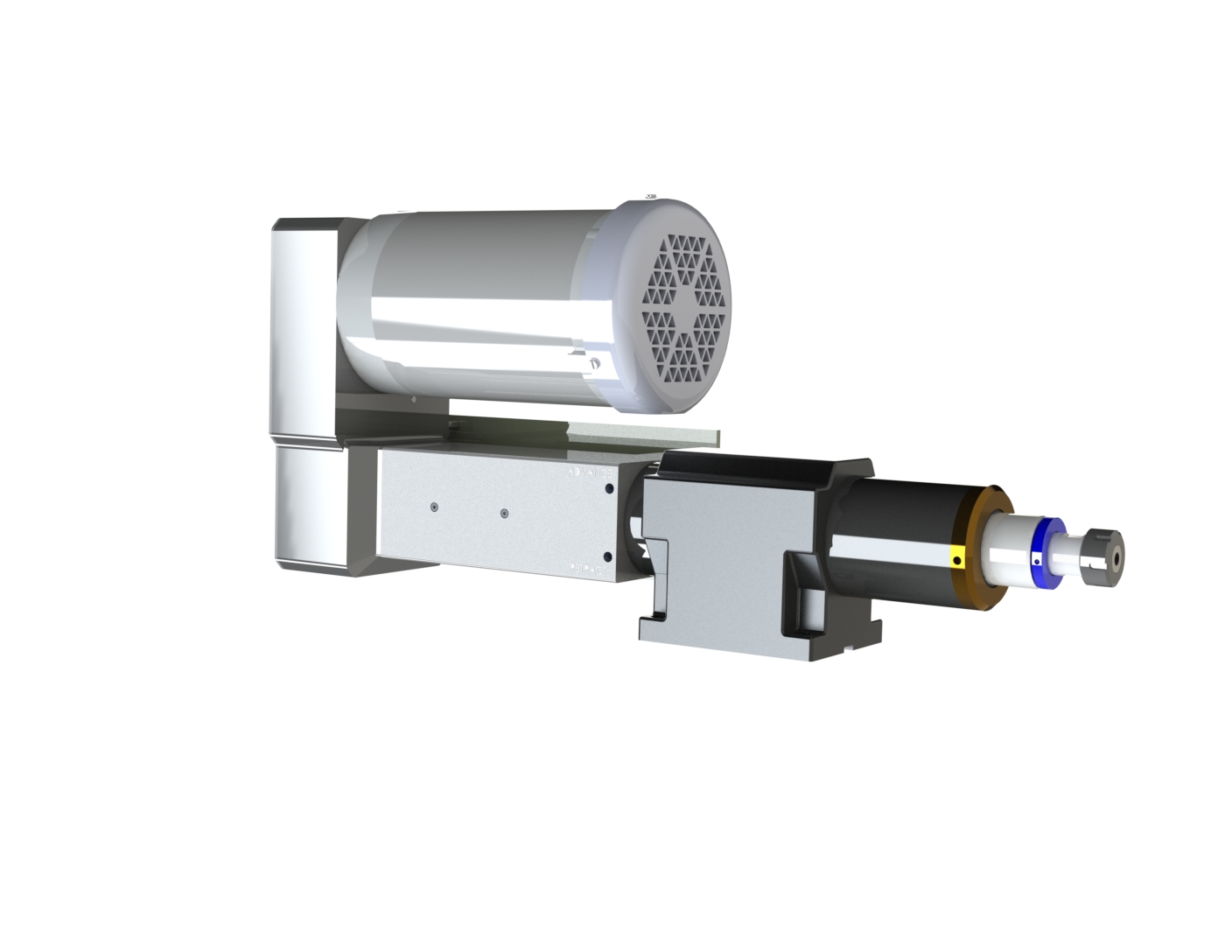

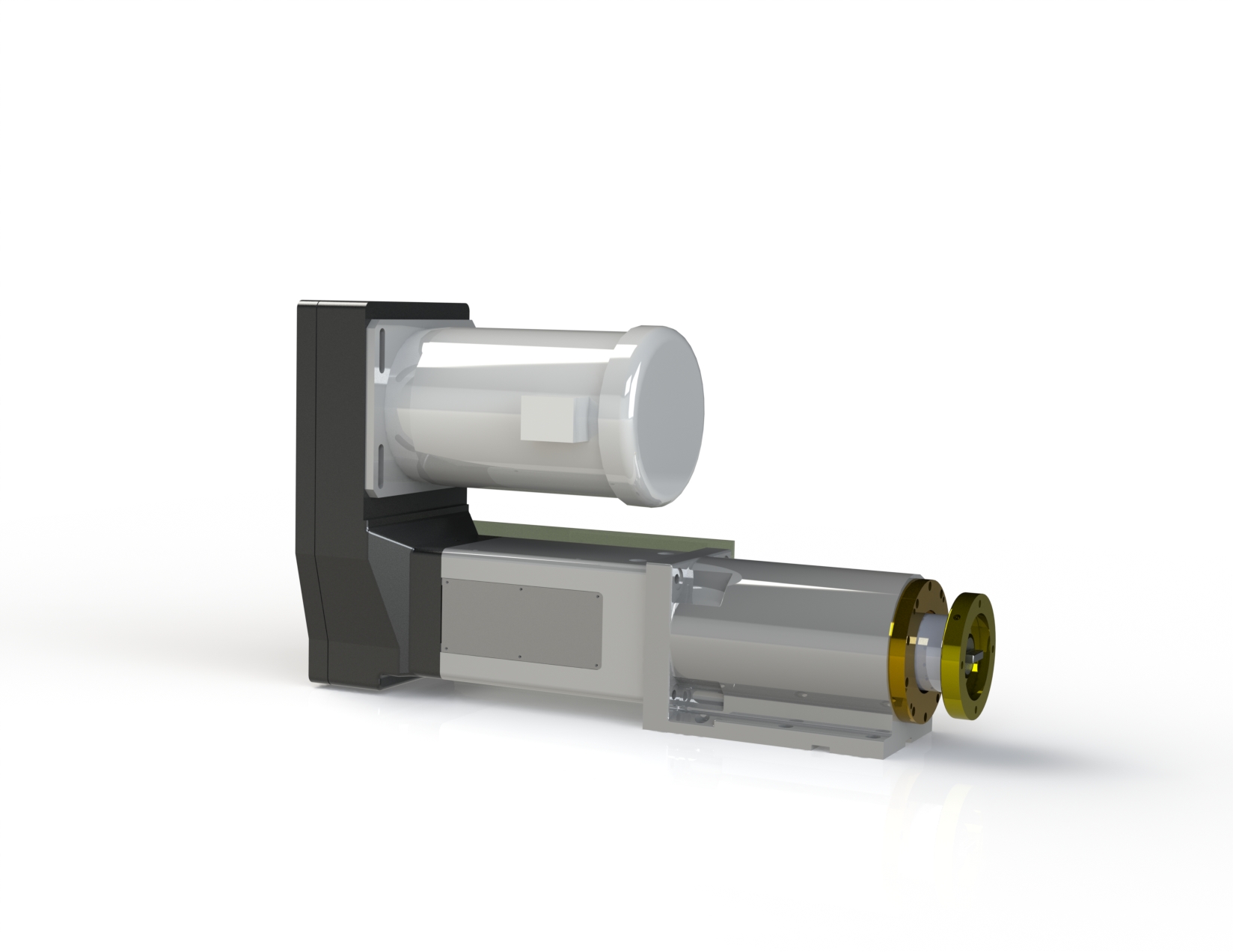

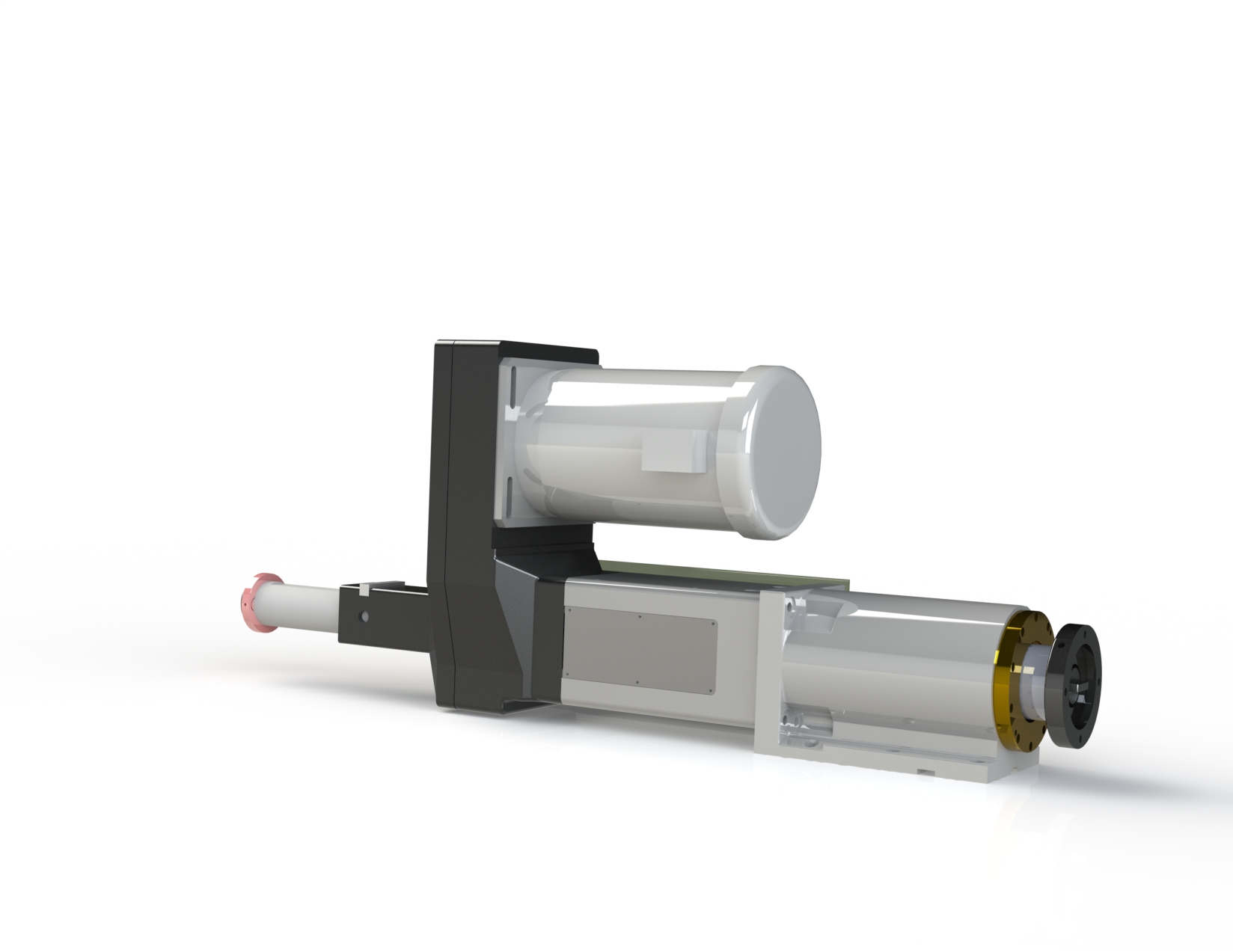

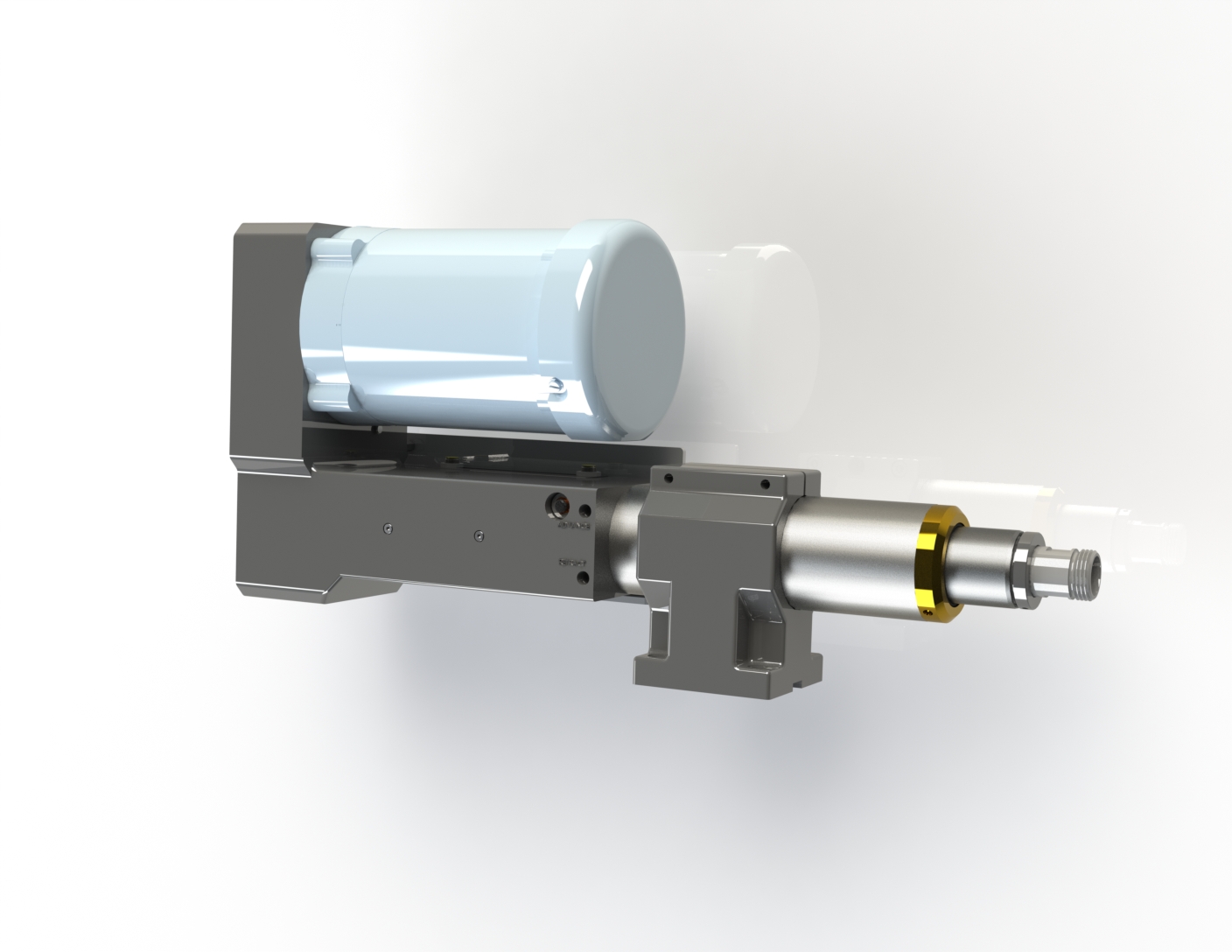

Zagar Pneumatic and Hydraulic Thrusters series drilling units are capable of meeting a wide variety of production requirements. Available in three basic thrust sizes, they offer a solid solution for drilling operations. Requiring both rapid advance and controlled feed. The same unit features the choice of pneumatic or hydraulic operation, powered by a three- phase 230/460 V motor.

Zagar Tapping units incorporate a lead screw assembly with our standard drilling units. Tapping units are powered by a reversing brake motor. These serve a wide range of tapping applications, accommodating pitch sizes from 8 to 56 TPI (metric sizes also available) and motor sizes up to 7.5 HP.

FEATURES AND BENEFITS

- Greater drilling thrust since our double acting cylinder requires no springs for return

- Efficient power transmission actuated by our involute spline driven spindle

- Rear support bearing on spindle makes for higher radial load capability and reduced spline wear.

- Spindle TIR of .0005”

- Adjustable positive stop with .0005” repeatability for accurate depth control

- Peck feed options for seep hole drilling in small diameters

- Quick speed changes made possible through the interchangeable synchronous belt and pulley kits

http://www.youtube.com/channel/UCLme4uPzZ9w2N_VdWFxoQ7Q for the Zagar YouTube Channel

- Wide variety of spindle nose options including; Jacob’s Taper, drill head tang drive and Zagar threaded nose for standard Zagar Accessories.

- Protective guarding for operator safety

- 1,2 or 3 limit sensor kits for full-back, full-depth, and peck of intermediate positioning control.

- Adjustable limit sensor cams

- Standard four limit sensor kit provided for tapping units.

- Easily interchangeable lead screw and nut assembly, enabling quick changeover of tap pitches (tap units only)

- Oil mist assembly for automatic lead screw and nut fabrication. (tap units only)

DRILLING AND TAPPING SPECIFICATIONS

DRILLING UNITS

| Machine-Part number | Stroke | Thrust Capacity @100 PSI | Rapid Traverse | Quill Diameter | Feed Rate | Max. Spindle RPM | Min. Spindle RPM | Max. Drilling Capacity IN. Alum/Cast Iron | Motor HP STD/OPTIONAL |

|---|---|---|---|---|---|---|---|---|---|

| 789-590 | 6 | 584lbs | 200 | 2in. | .5-20 | 6900 | 570 | 1.334/.671 | 1.5/2 |

| 789-1090 | 6 | 1178lbs | 300 | 3in. | .5-20 | 6900 | 570 | 1.34/.6719 | 2.0/3.0 |

| 789-2090 | 8 | 2200lbs | 400 | 4in | .5-20 | 3943 | 387 | 2.0/1.0 | 3.0/5.0 |

TAPPING UNITS

| Machine-Part number | Stroke | Thrust Capacity @100 PSI | Rapid Traverse | Quill Diameter | Feed Rate | Max. Spindle RPM | Min. Spindle RPM | Max. Drilling Capacity IN. Alum/Cast Iron | Motor HP STD/OPTIONAL |

|---|---|---|---|---|---|---|---|---|---|

| 789-690 | 6 | 584lbs | 300 | 2in | .5-20 | 6141 | 450 | 1″-8/; 5/8-11 | 1 or 2/2@1140 |

| 789-1190 | 6 | 1178lbs | 300 | 3in | .5-20 | 6900 | 380 | 1-1/2″-6/1-8 | 2.0/3.0 |

| 789-2190 | 6 | 2200lbs | 300 | 4in | .5-20 | 3943 | 400 | 2″-4/1-3/8-6″ | 5/7.5 |