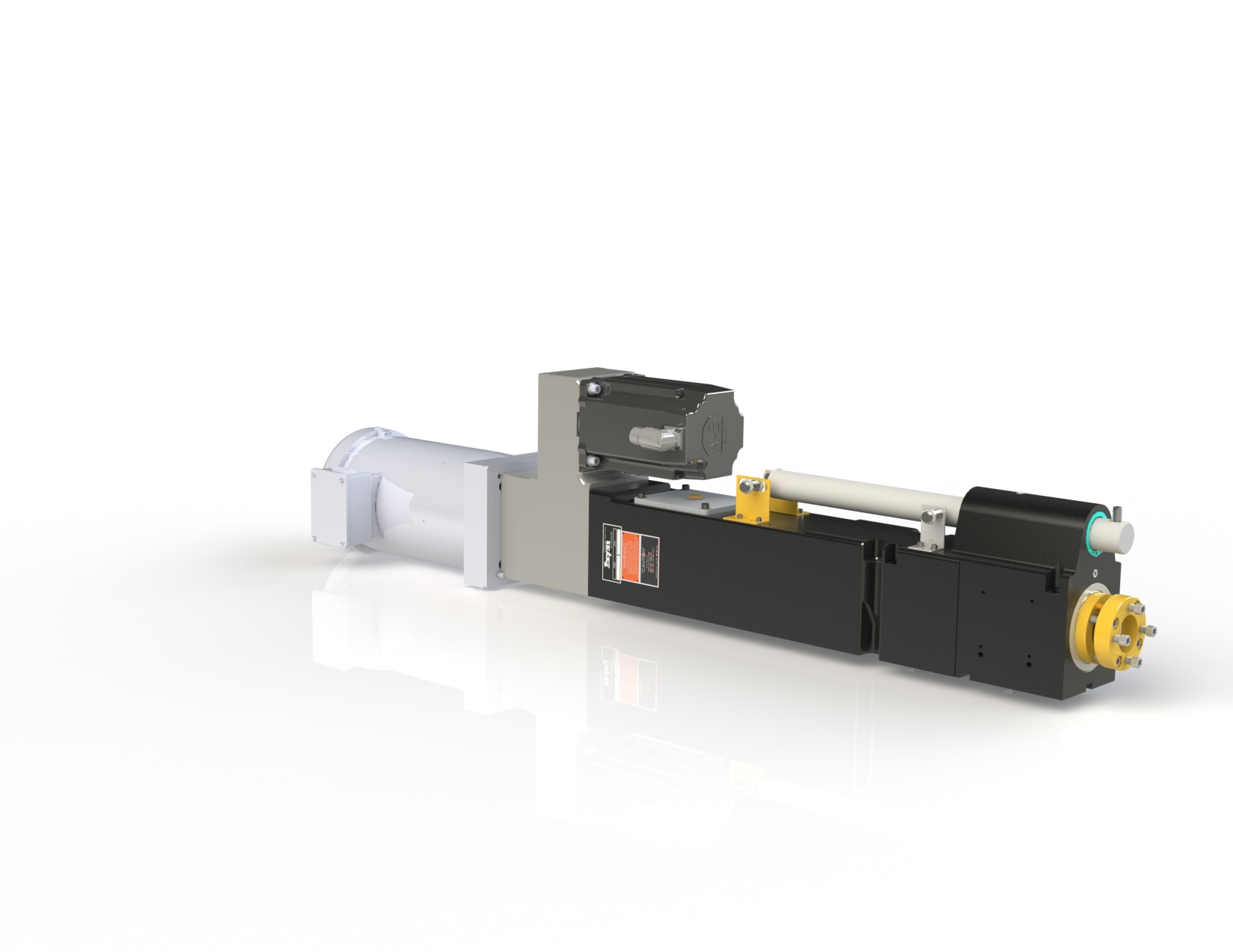

MQ10 Feed Units

The model MQ10 is a ball screw feed unit offered by Zagar Inc. Like other models, it is ideally suited for applications utilizing computer controlled technology. Furthermore, the unit is available with variable speed spindle and quill feed servo motors, machining operations from drilling to tapping can be easily accomplished. Fortuntely, the unit features a large hardened and ground quill which carries the spindle and ball nut, mounted in a cast iron housing.

http://www.youtube.com/watch?v=m5J3tXcqWBs for Feed Unit video.

http://www.zagar.com for Zagar Home Page.

OVERVIEW MQ10 FEED UNITS

- MQ10 Feed Units applications: Drilling, Reaming, Counterboring, Spot-facing, Hollow Milling, Recessing, Deep Hole Drilling, Chamfering and tapping

- Capabilities: Dual Feed, Back Feed, Forward and Back Feed, Peck Feed, Jump Gap Cycle are all applications to show the flexibility of this unit

- Servo Motor can be controlled by programmable controller or microprocessor

- Ballscrew centerline thrust design provides stability through unit stroke

- Mechanical drive provides consistent, effective feed rates for maximum production

- In line, Positive stop provides accurate depth control without deflection of the quill

- Optional coolant package and flanged Spindle nose for “Quick Change” chuck type tool holders

- Cast Iron Construction

Specifications

- Stroke: 12″

- Thrust Capacity 2000 Lbs

- Rapid Traverse Rate: 315 IPM

- Feed Rates:.5 to 200 IPM

- Depth Control: Adjustive Positive Stop

- Quill Diameter: 3 Inches

- Spindle Noses: 1.0625 to 1.375 Adj. Adapter or head drive

- Minimum Spindle Speed: 3:1 Reduction

- Maximum Spindle Speed: 7200 RPM

- Spindle Torque Capacity: 400 in. Lbs.

- Mounting Positions: Unlimited