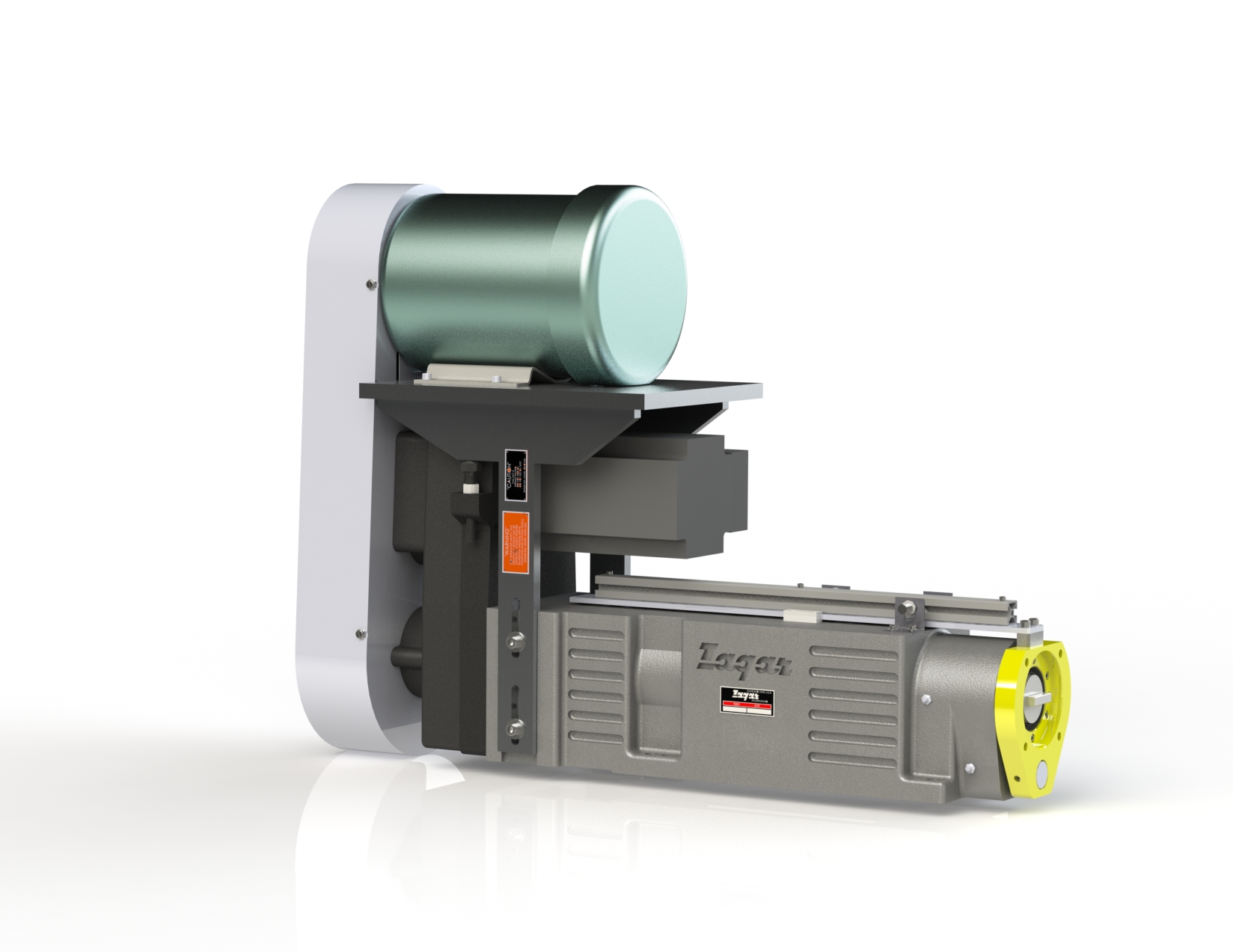

MQ120 Feed Units

OVERVIEW OF MQ120 FEED UNITS

- Applications: Drilling, Reaming, Counterboring, Spot-facing, Hollow Milling, Recessing, Deep Hole Drilling, Chamfering and tapping

- Capabilities: Dual Feed, Back Feed, Forward and Back Feed, Peck Feed, Jump Gap Cycle are all applications to show the flexibility of this unit

- Servo Motor can be controlled by programmable controller or microprocessor

- Ballscrew centerline thrust design provides stability through unit stroke

- Mechanical drive provides consistent, effective feed rates for maximum production

- In line, Positive stop provides accurate depth control without deflection of the quill

- Optional coolant package and flanged Spindle nose for “Quick Change” chuck type tool holders

- Cast Iron Construction

http://www.zagar.com for the Zagar Home Page

https://www.youtube.com/watch?v=m5J3tXcqWBs for Feed Unit Demonstraition

Specifications

- Stroke: 12″

- Thrust Capacity 3200 Lbs

- Rapid Traverse Rate: 315 IPM

- Feed Rates:.5″ to 200 IPM

- Depth Control: Positive Stop

- Quill Diameter: 4250 Inches

- Spindle Noses: 1.0625 to 1.875 Adj. Adapter and head drive

- Minimum Spindle Speed: 3:1 Reduction from Motor RPM

- Maximum Spindle Speed: 6000 RPM

- Spindle Torque: 1300 LBS

- Mounting Positions: Unlimited